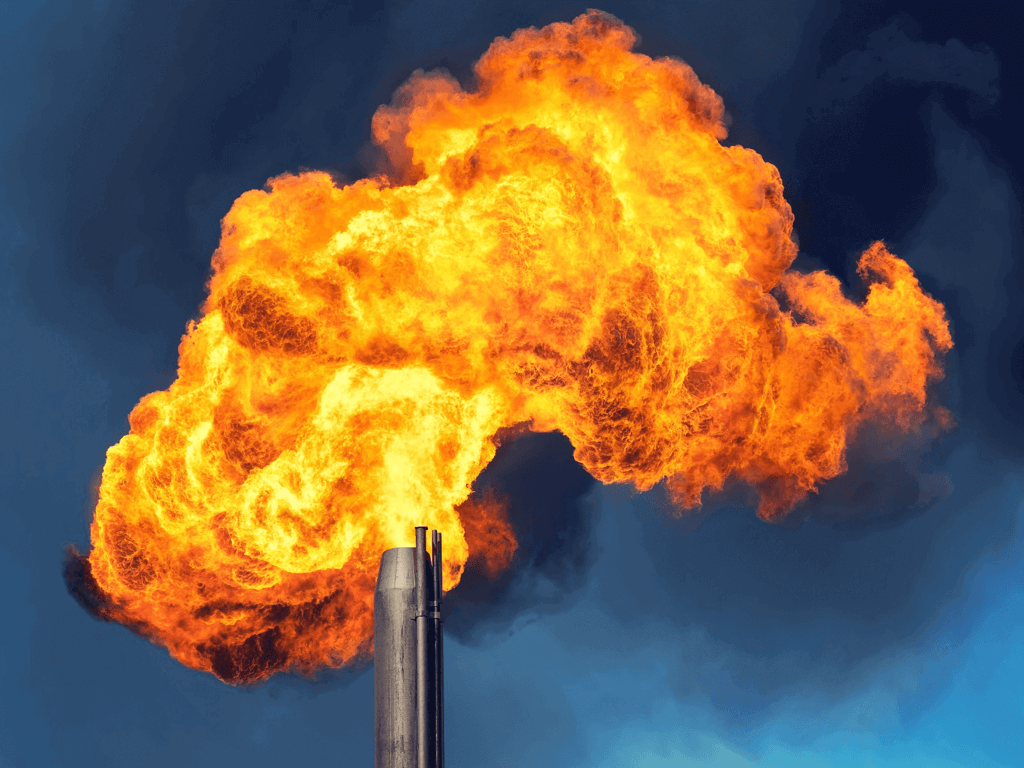

Complete flaring elimination at locations with a minimum of 350 MCF flared a day. No CO2 emissions caused by flaring where EZ Smartgrid™ System is deployed.

Meet rapidly growing regulations and tightening environmental guidelines without interruptions of the operation by reducing harmful emissions.

Zero upfront cost to producers. Additional royalties to landowners by bringing flared gas to market on-site without building physical pipeline infrastructure.

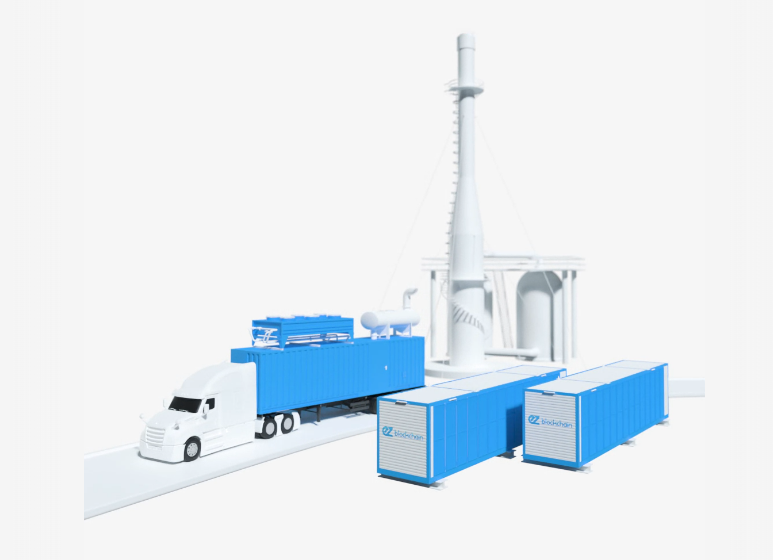

EZ Blockchain developed a plug-and-play solution to turn natural gas flaring into monetization. EZ Blockchain deploys the EZ Smartgrid™ Flaring Mitigation System (FMS) right on the oil well pads to turn wasted natural gas into a new revenue stream, meeting new environmental regulations along the way

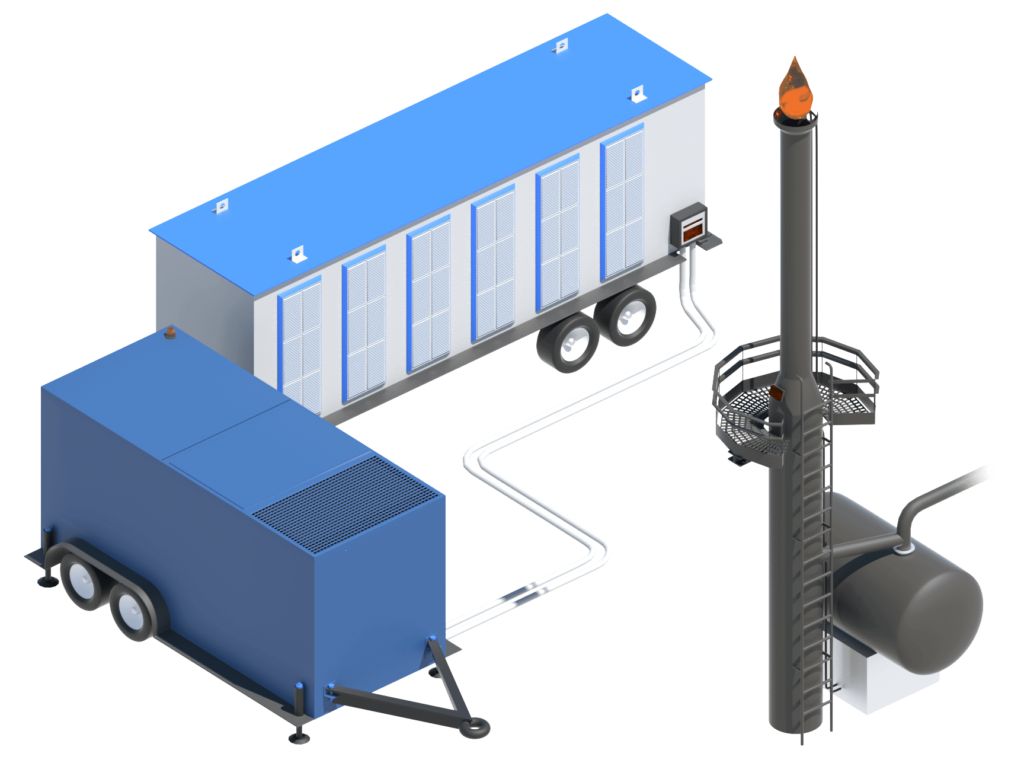

It consists of a mobile gas engine generator which converts wasted, flared gas into electricity which is immediately used onsite to power the mobile data center, EZ Smartbox.

EZ Blockchain developed a mobile flaring mitigation system available to be deployed right on the oil well pad to reduce flaring.

This unique system does not require connection to the grid, all electricity produced is used onsite.

Instead of flaring wasted associated gas can be harnessed by gas engine generator to produce electricity, then the electricity is used to power mobile data center on the well pad without distributing energy to the grid.

Complete flaring elimination at locations with a minimum of 350 MCF flared a day. No CO2 emissions are caused by flaring where EZ Smartgrid™ System is deployed.

Meet rapidly growing regulations and tighten environmental guidelines without interruptions of the operation by reducing harmful emissions.

Zero upfront cost to producers. Additional royalties to landowners by bringing flared gas to market on-site without building physical pipeline infrastructure.

A power generation company was looking for a solution to diversify its revenue and build a demand response system that could consume power at the off-peak hours.

EZ Blockchain redesigned the mobile data center with a unique shelving system and airflow system to bring its capacity up to 2.5 MWs, installing 720 x Bitmain S17 type miners. Our engineering team had to design a separate electrical room built from scratch to make the work of the electrical operations team simpler and safer. The design of the mobile data center was divided into 6 separate sections, each having its own autonomous electrical surge protection infrastructure to operate each section independently.

The company’s team developed a simple from an operational perspective but complex from an engineering perspective filter louver door in each section. This optimized the effort of changing filters on a constant basis, reducing the amount of labor hours needed to perform the work.

EZ Blockchain delivered and installed a BTC mining box and associated miners with very little issues. The project is running smoothly, and a second box is on schedule to be delivered and installed.

This install will limit flaring at the field to a minimum, turning stranded gas into a profitable solution. The company designed the project from scratch, sourced crypto mining hardware in very tough market conditions.

After the installation, EZ Blockchain operates the crypto mining operation on a daily basis.

Tom Kirkwood

We’ve had the privilege of working with EZ Blockchain over the last year. Their support in getting our mine up and running was invaluable, saving us countless hours and maximizing uptime. Since start-up, we have been able to lean on their team 24/7 to help with mine optimization and troubleshooting. They are a trusted partner in our mining operations.

Joel Gordon